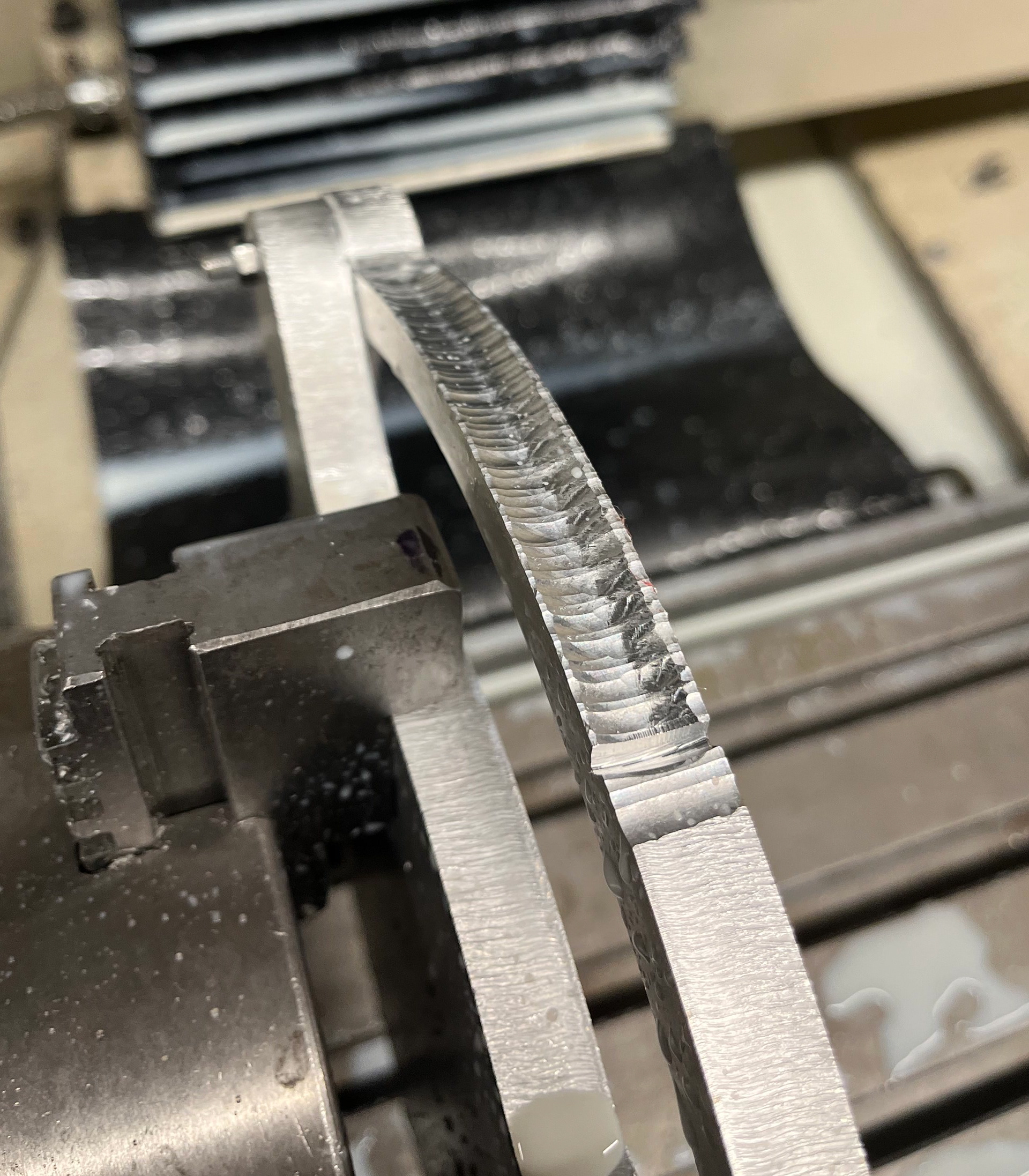

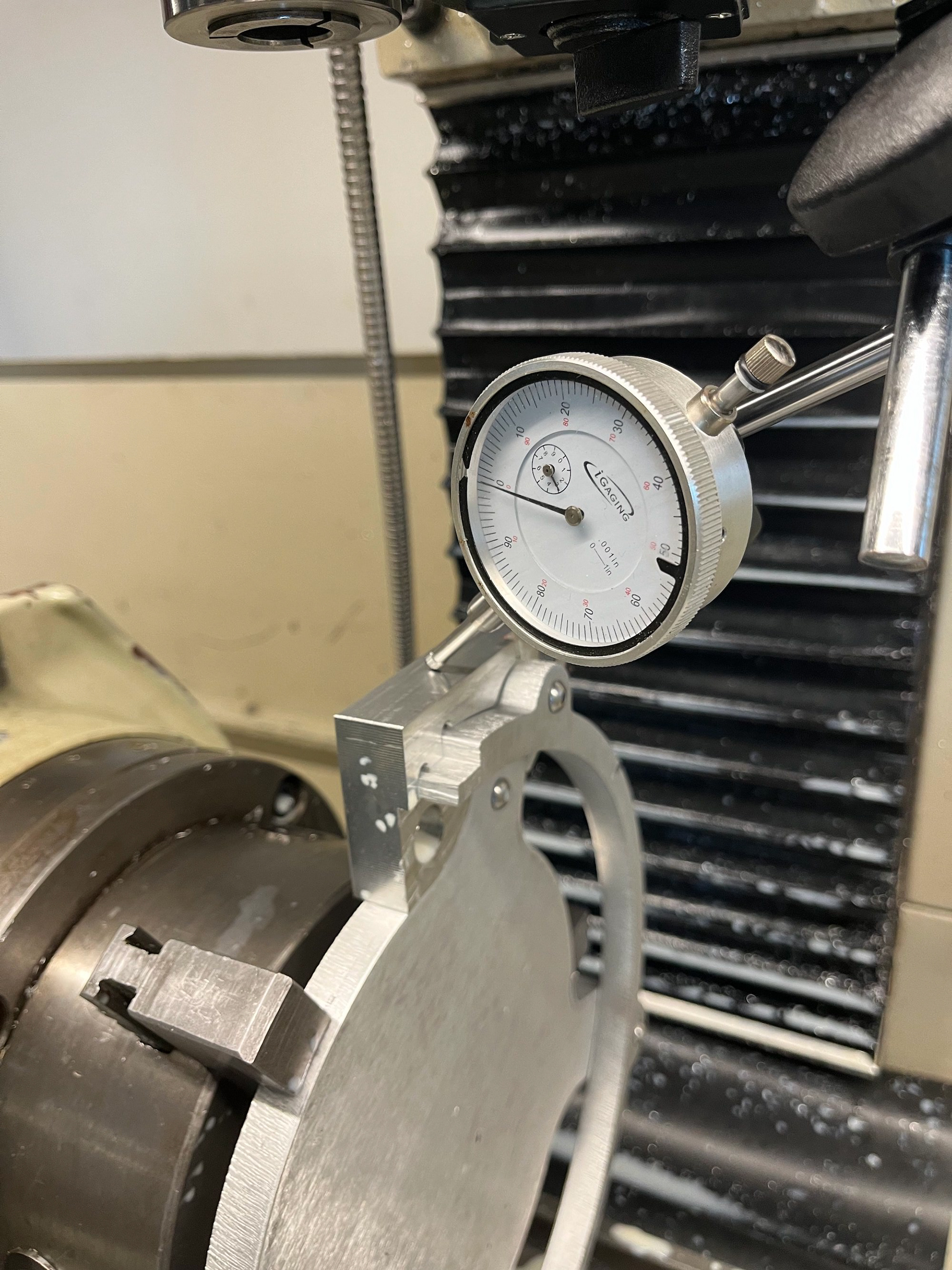

4-axis machining of a custom worm gear ring that I designed. The 4th axis on this Tormach was a bit broken, so a lot of debugging had to be performed during the machining process. Fixtures and jigs were also milled using the same machine. CAM paths generated in Fusion 360.

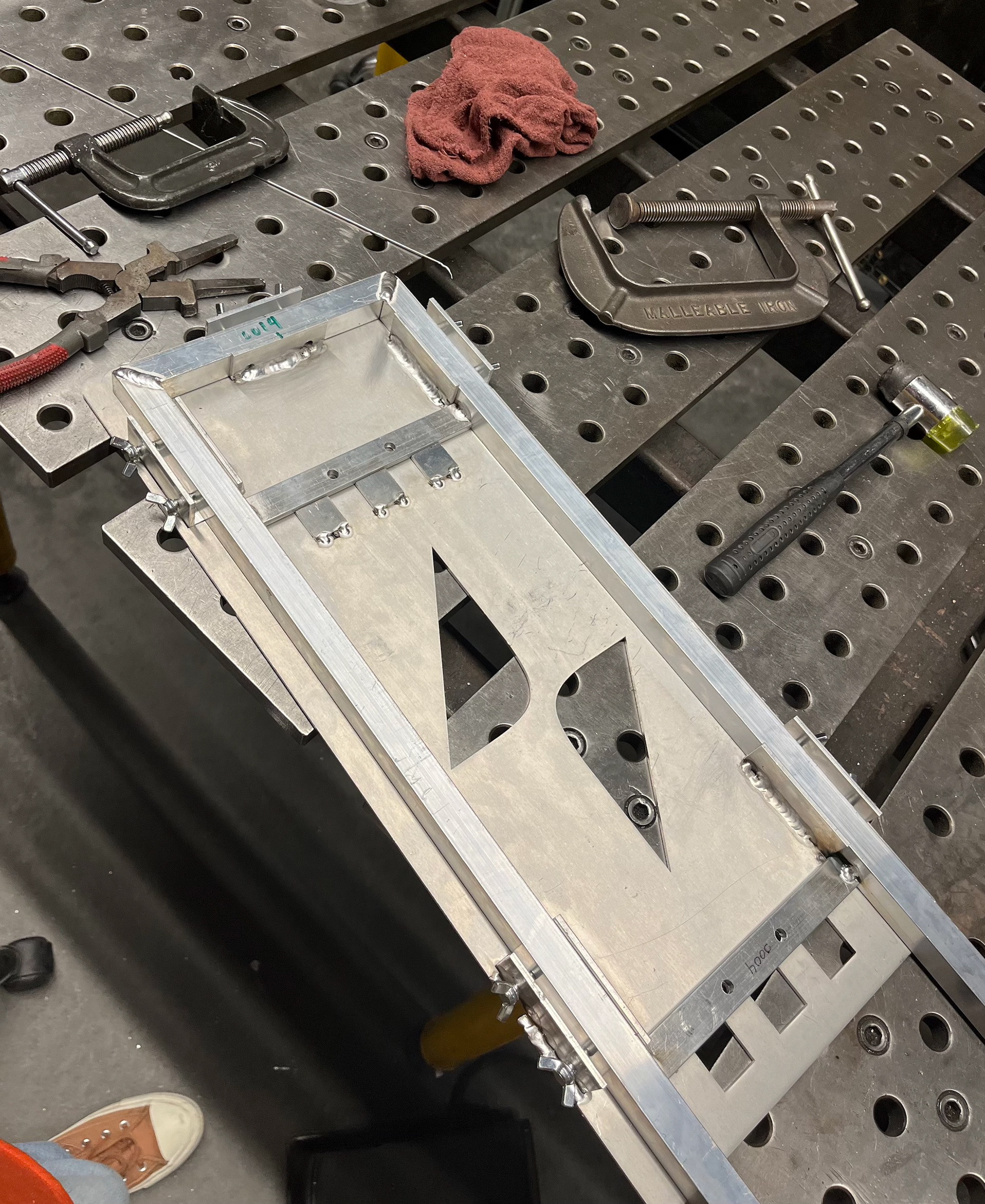

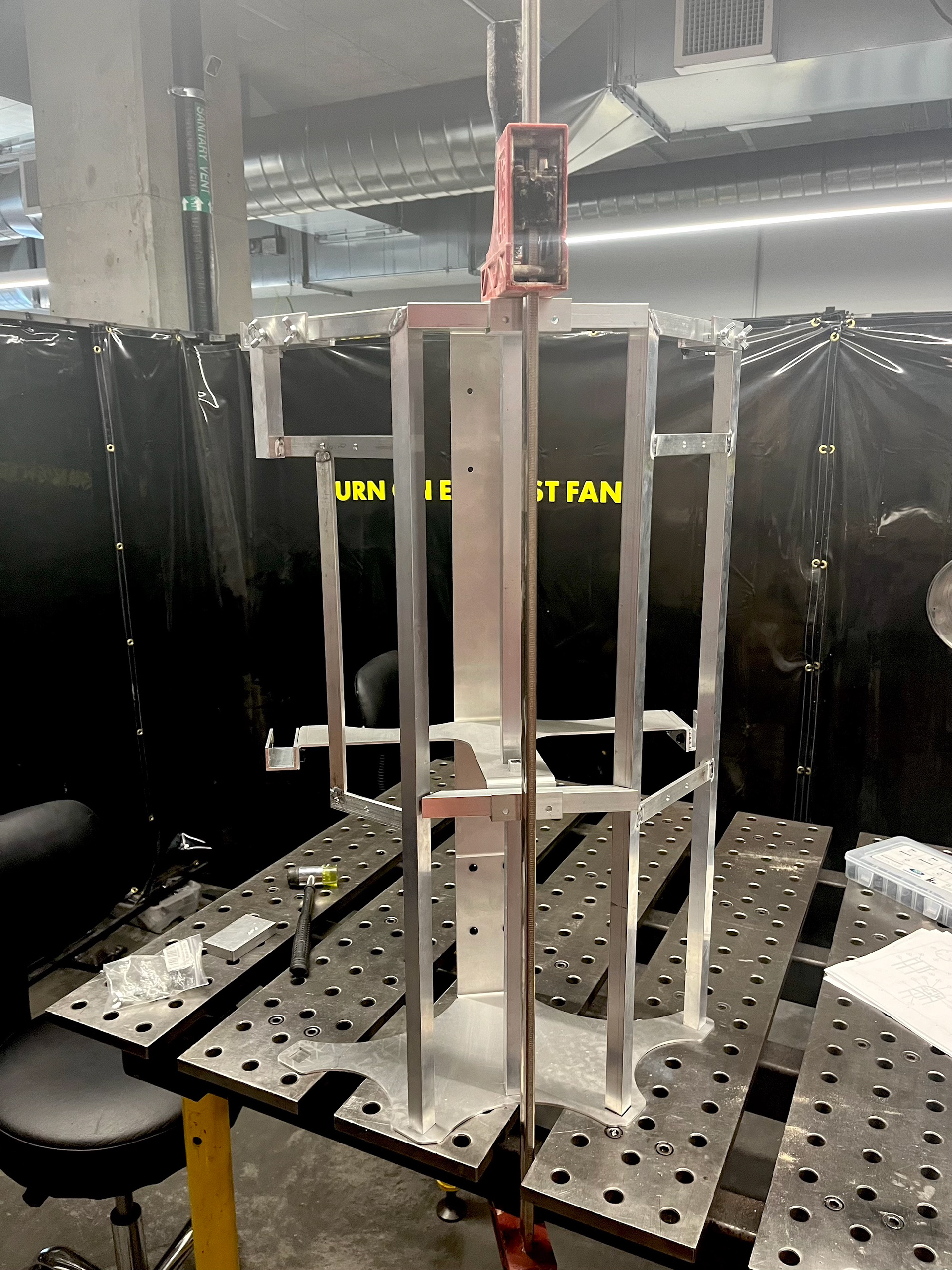

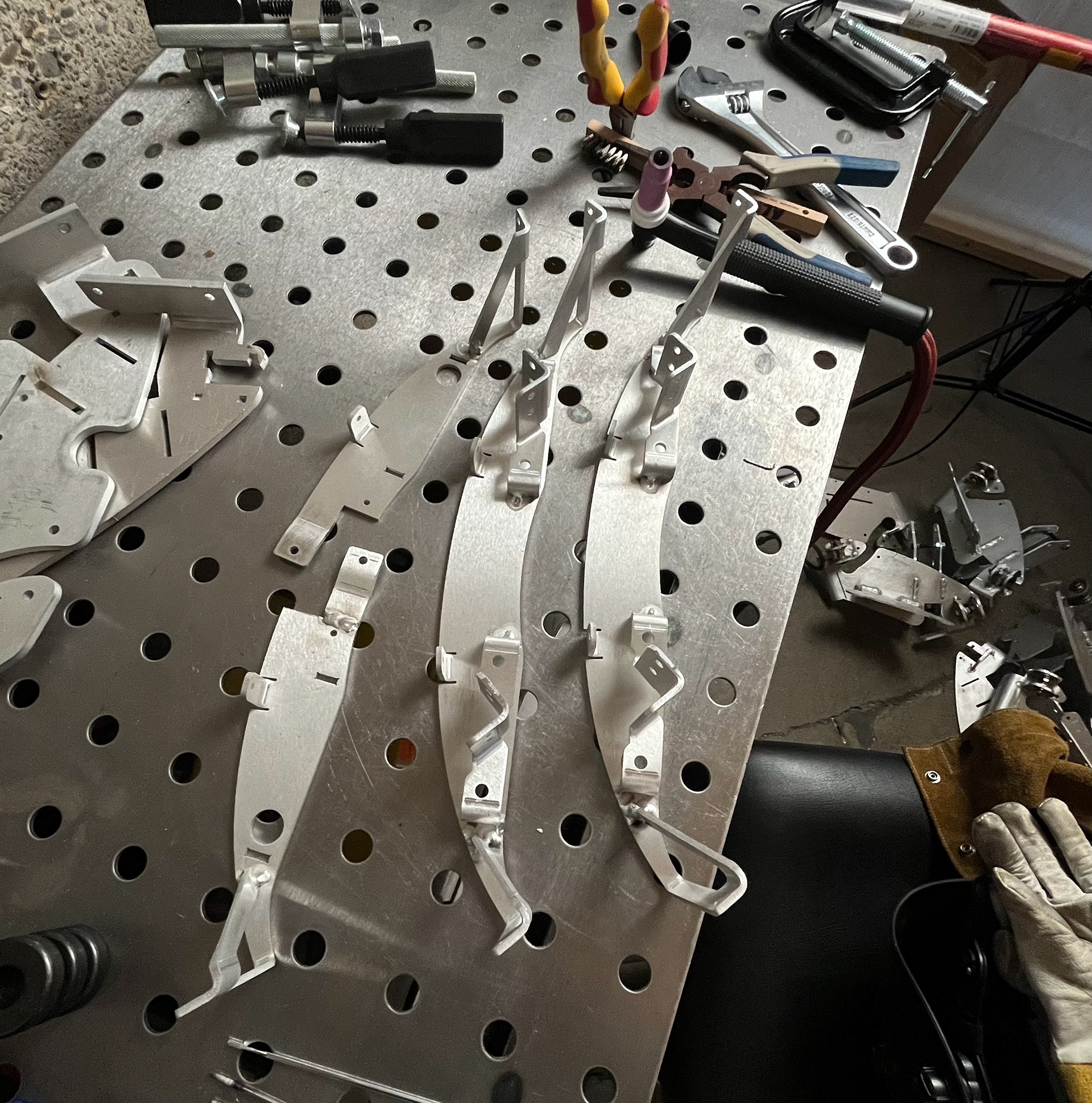

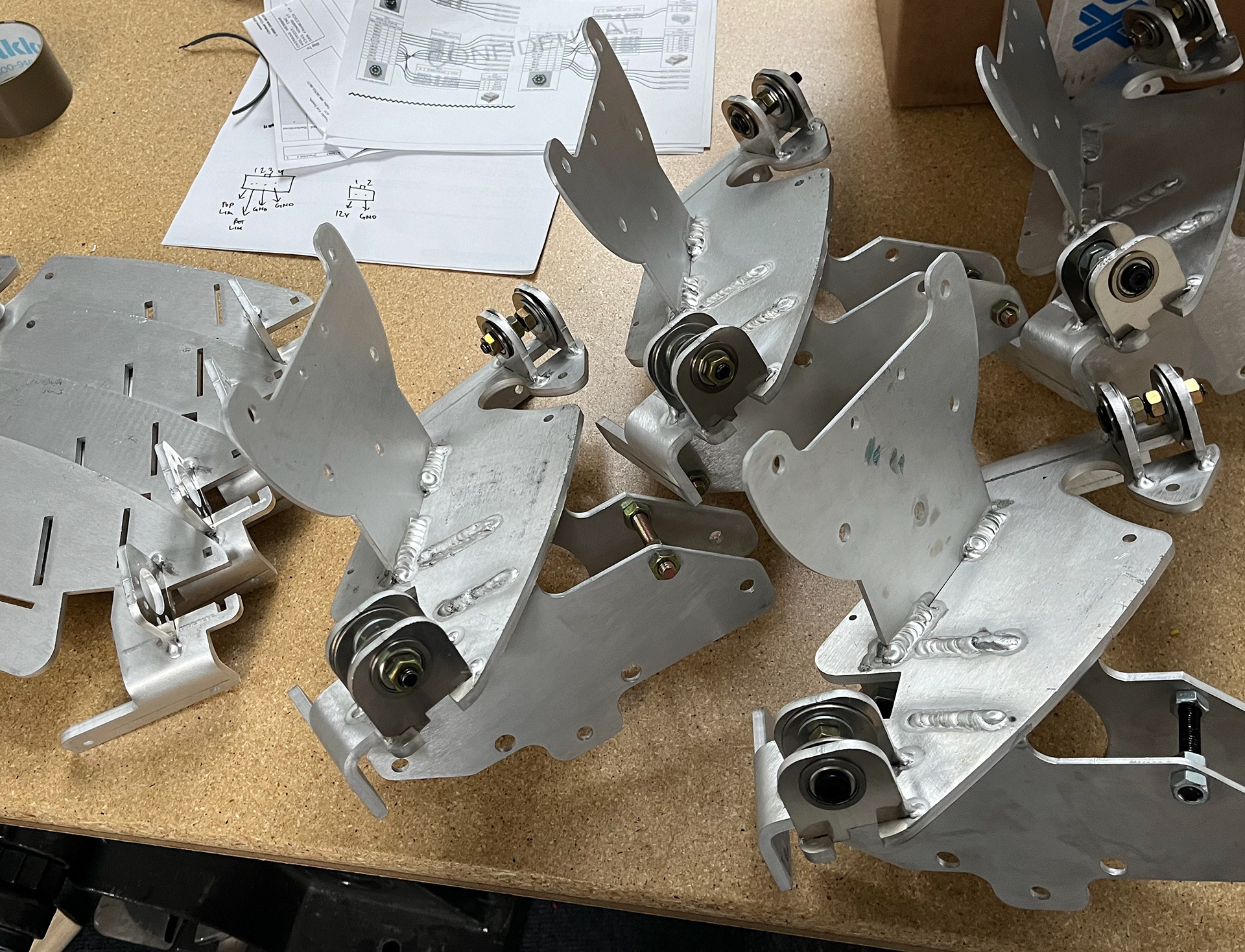

Various welding projects for prototyping, DFM validation, small batch production parts. Welding scope ranged from aluminum tubes to thin sheet metal to ½" thick fills.

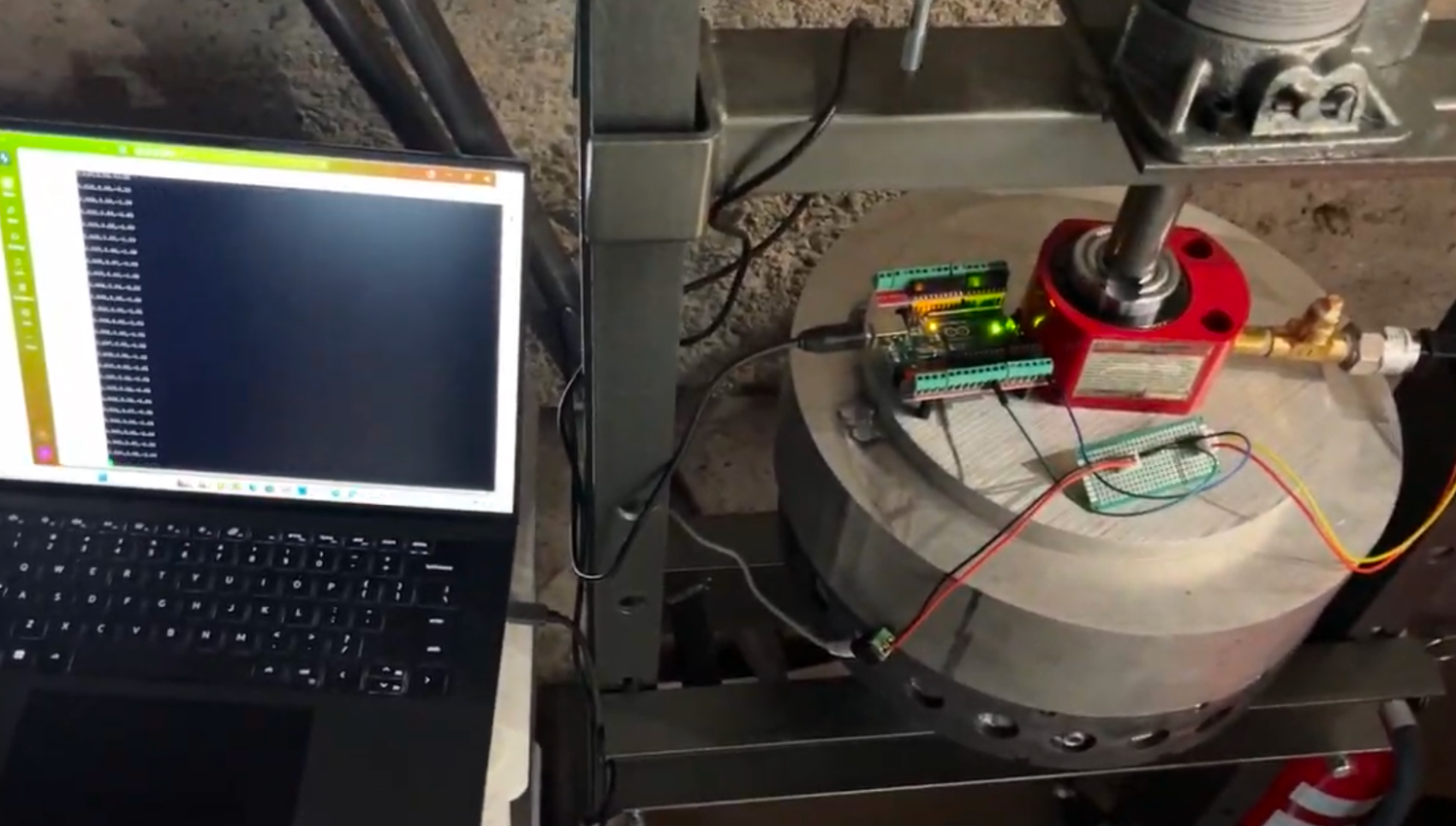

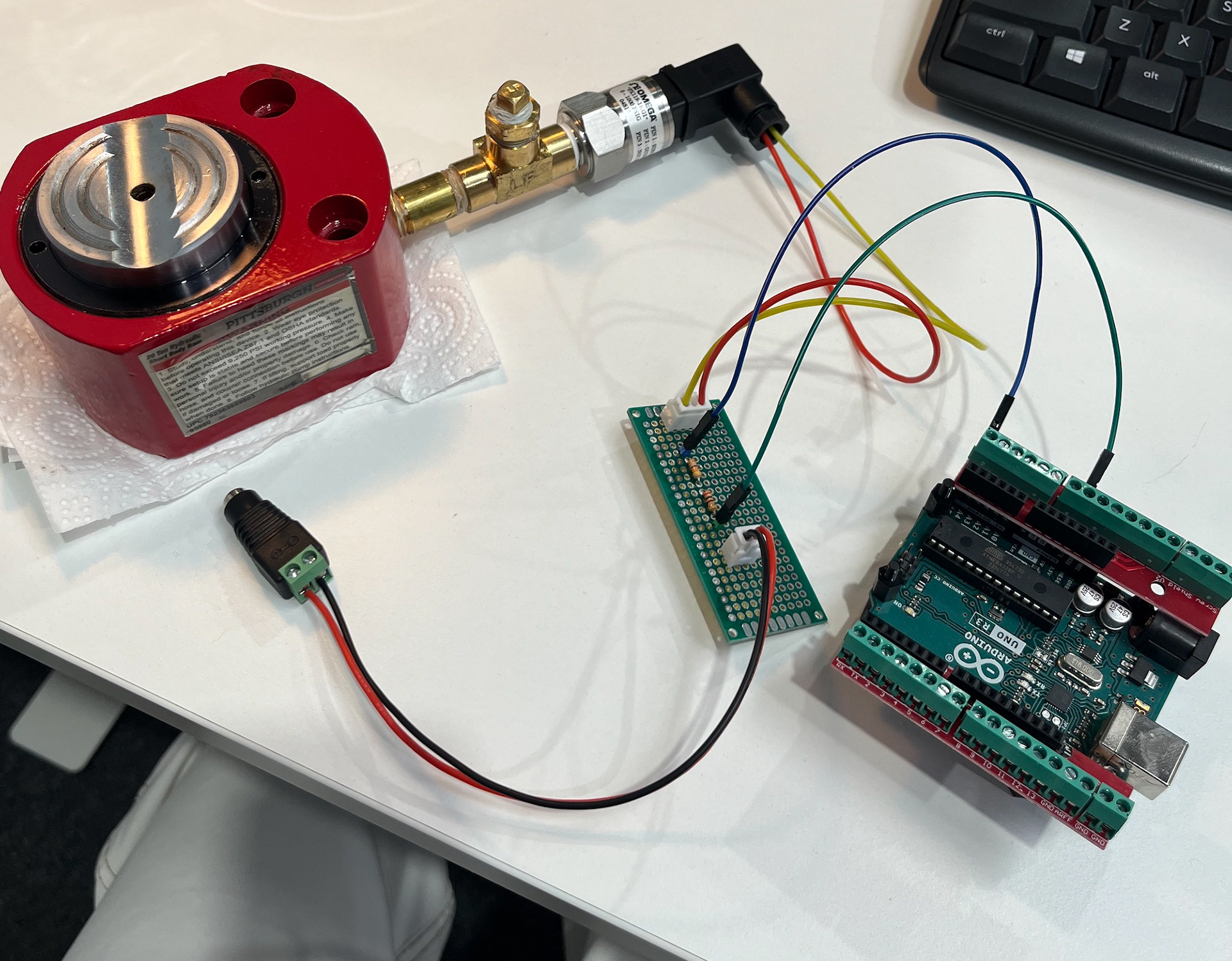

Conceptualizing, building, and conducting the mounting means load test for UL 2594 compliance. For this test, I wrote an Arduino program and created a simple circuit to collect and export data from a digital pressure transmitter fitted onto a converted hydraulic ram.

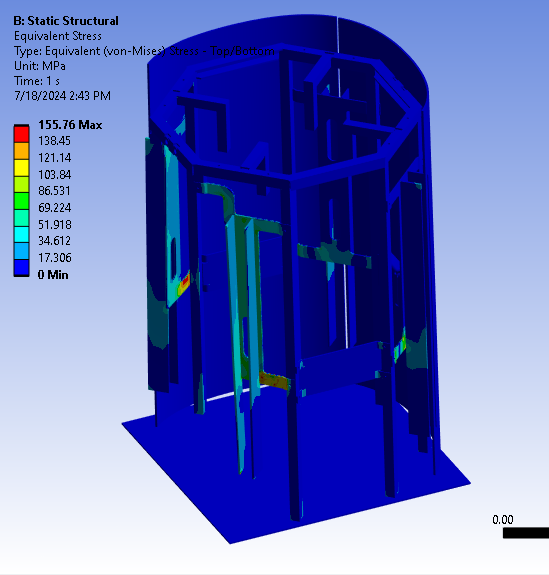

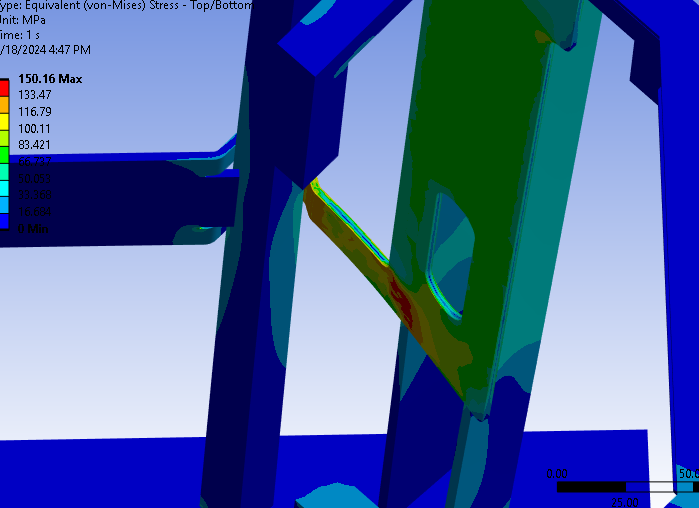

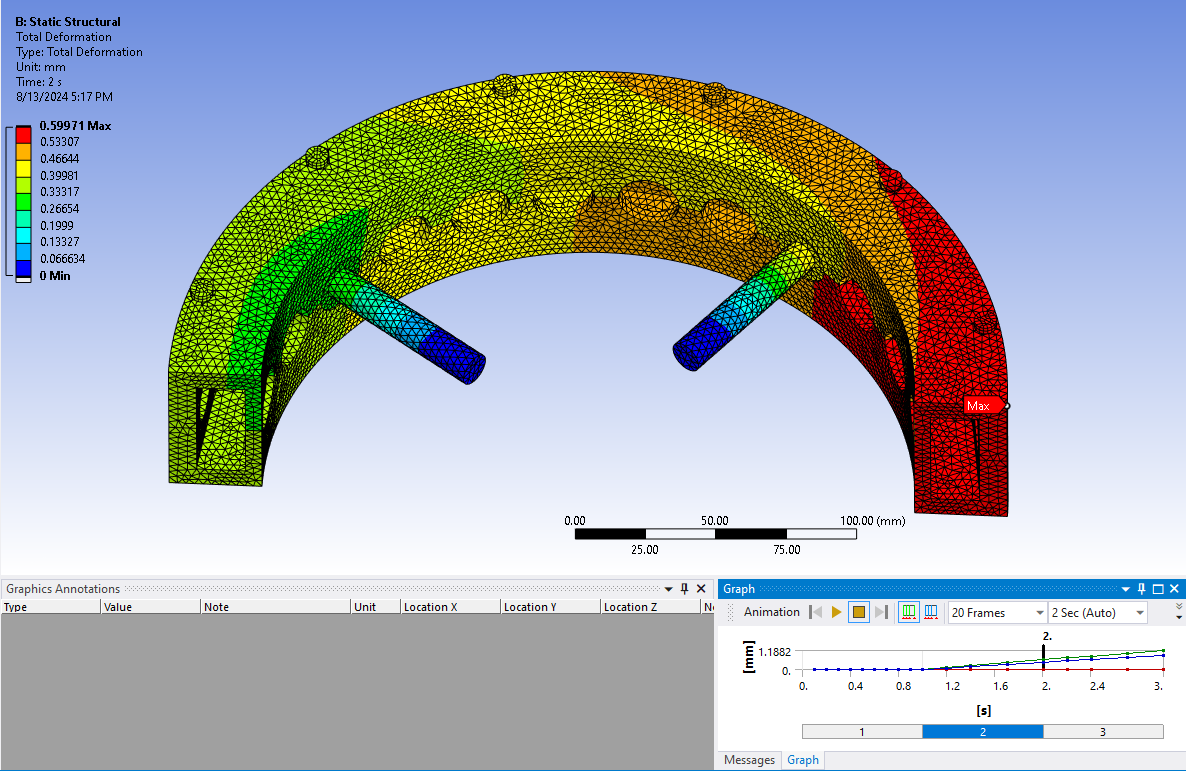

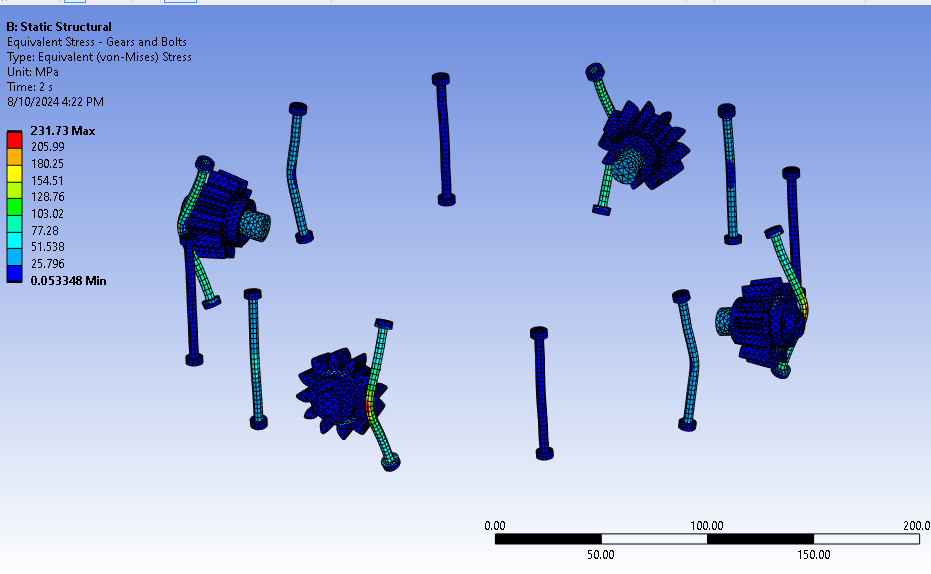

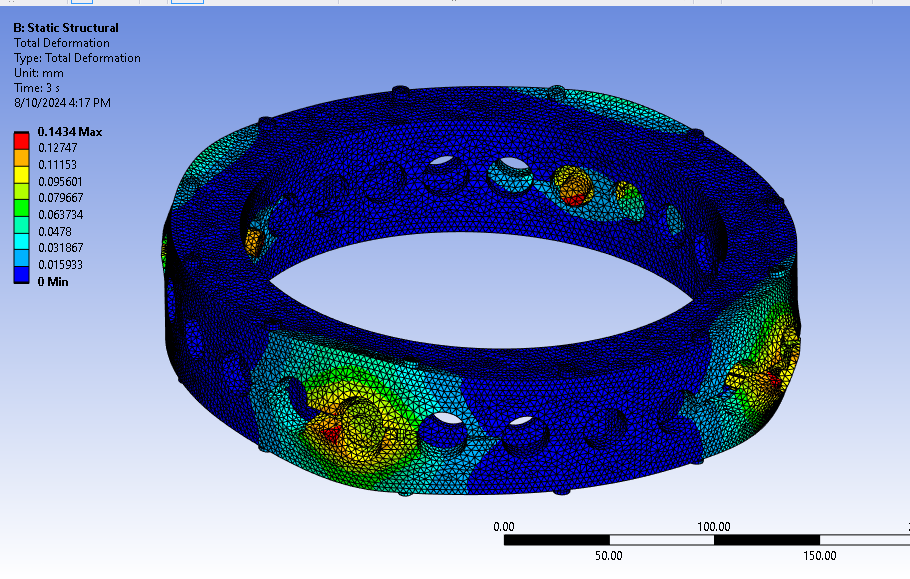

Examples of static structural FEA analysis to evaluate design feasibility, validate material selection, and identify failure modes.

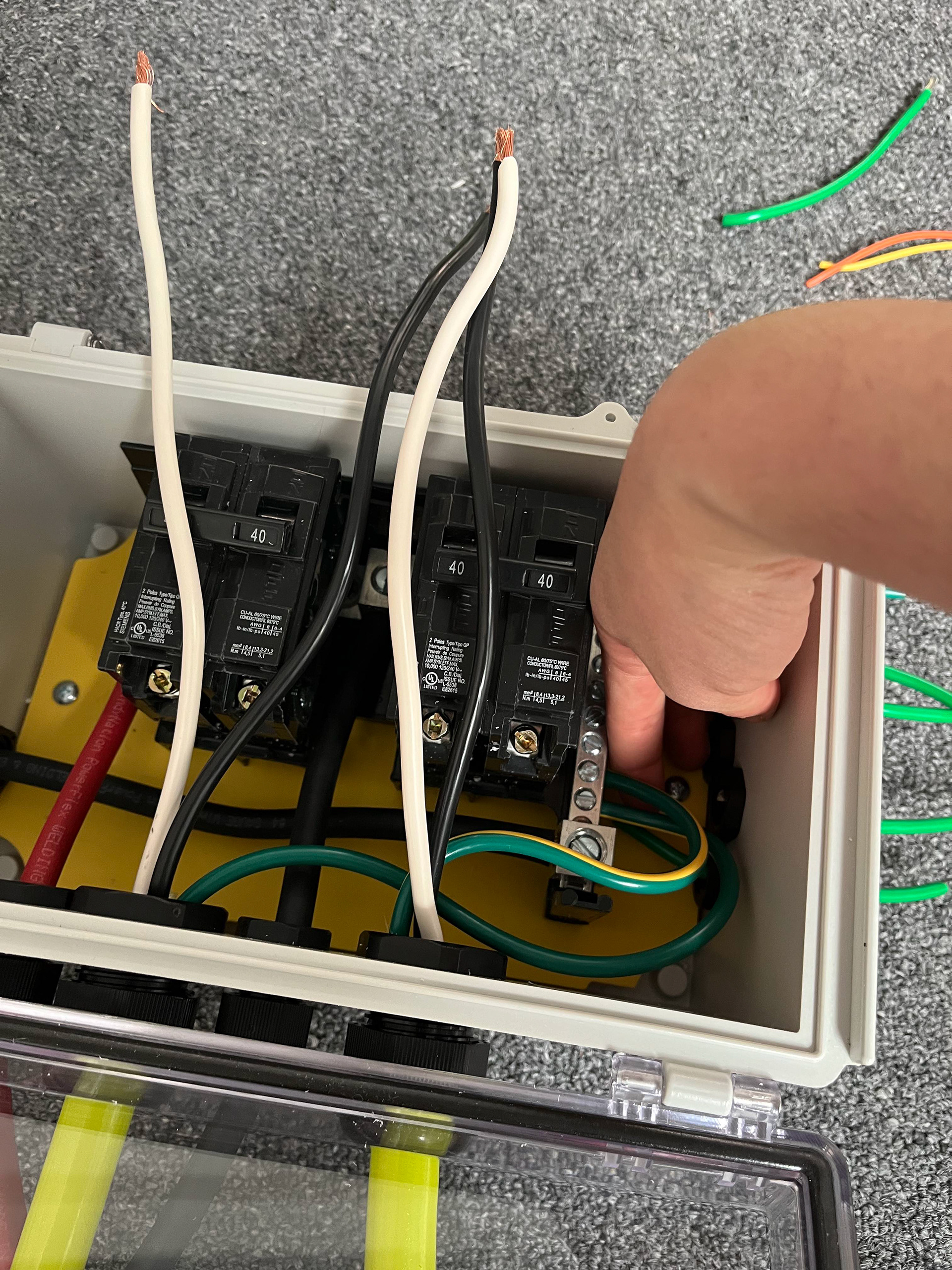

Prototyping, sourcing, and assembling the system's breaker box with custom cable harnesses, in accordance to UL safety standards.

Examples of designing for injection molding, die-casting, and extrusion (coming soon).

Photos from the first commercial deployment of Voltpost, in Oak Park, IL.