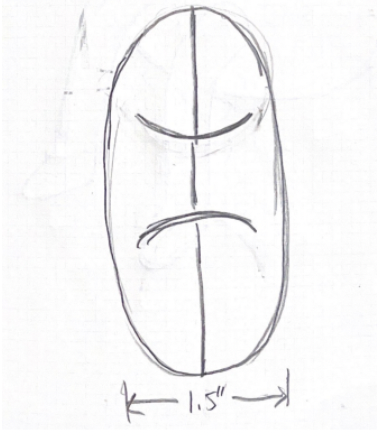

Initial ideation:

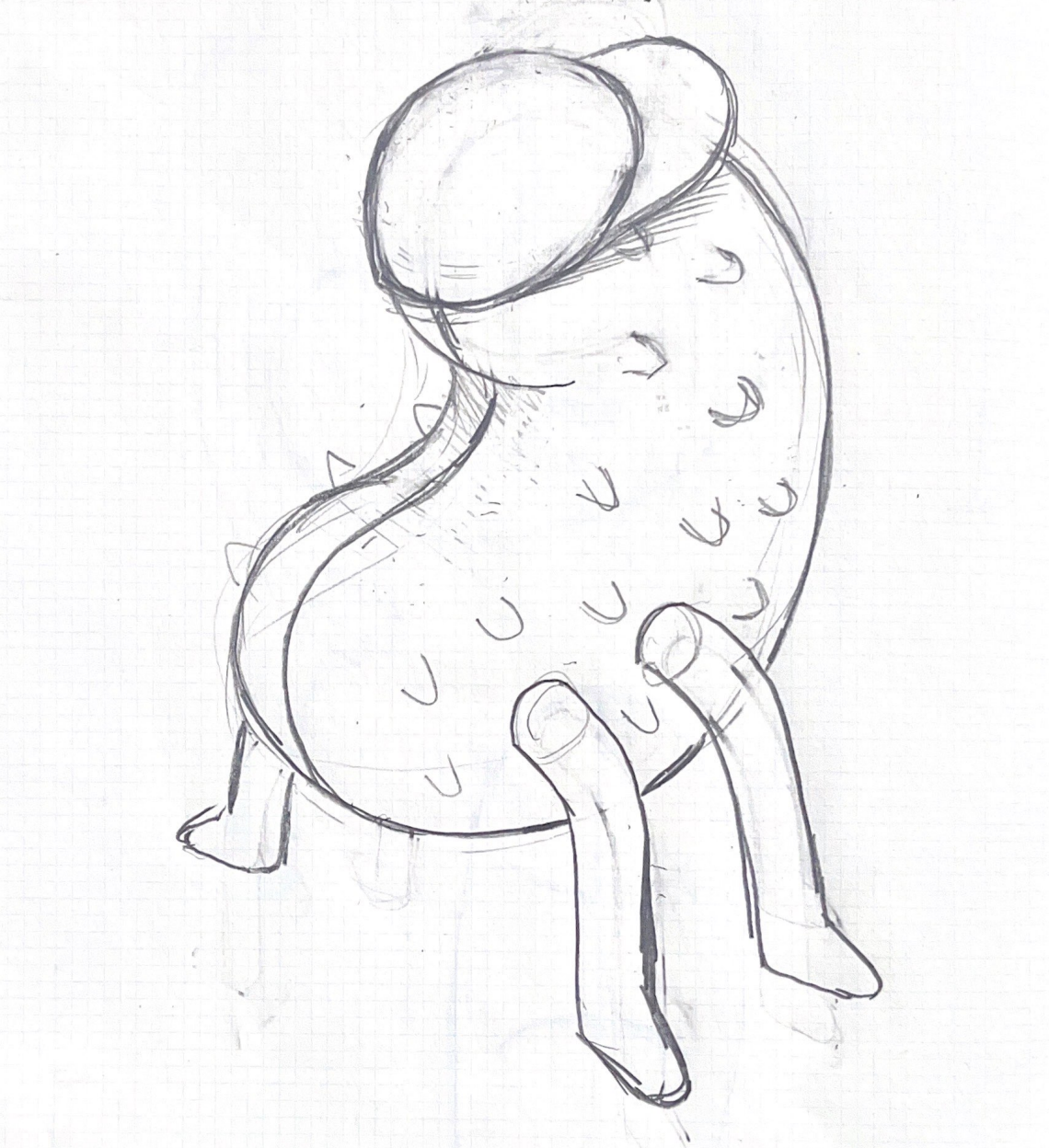

Initial sketches. Sandra's contributions: Drosophila Melanogaster kebab, covid cashew, finger fries

To start, each member came up with 3 sketches. After regrouping to discuss which direction to pursue, we ended up conjoining features from a few different sketches to offer the world a personified cashew outfitted with legs, COVID spikes, and a snapback hat—a phenomenon you didn't know you needed, if you ask me. Final hand sketch below:

Assembly

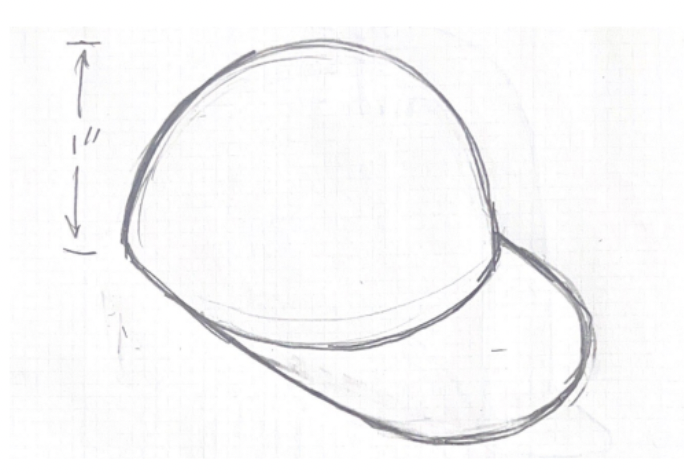

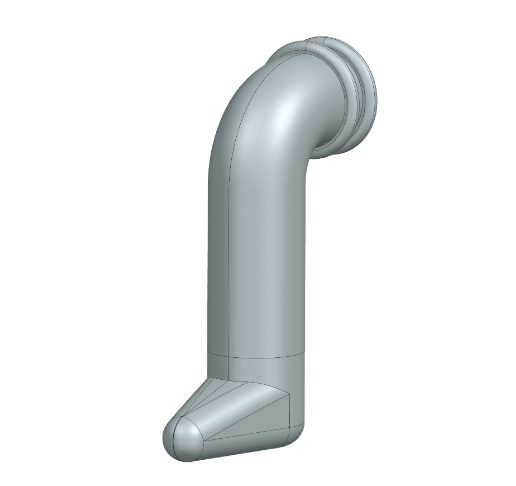

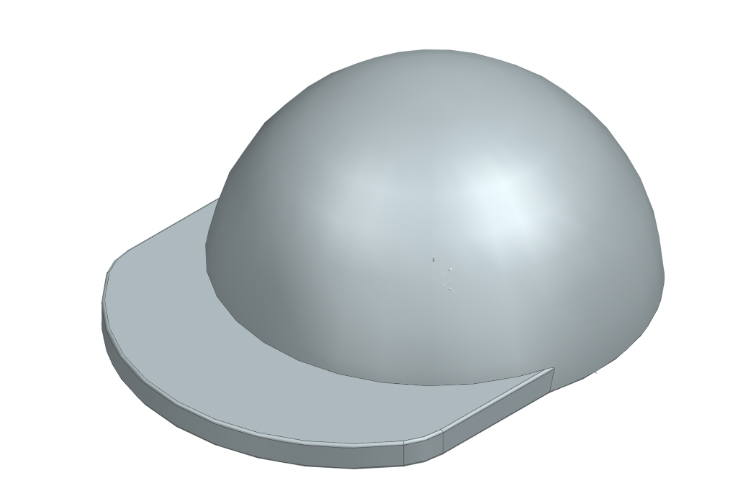

Hat

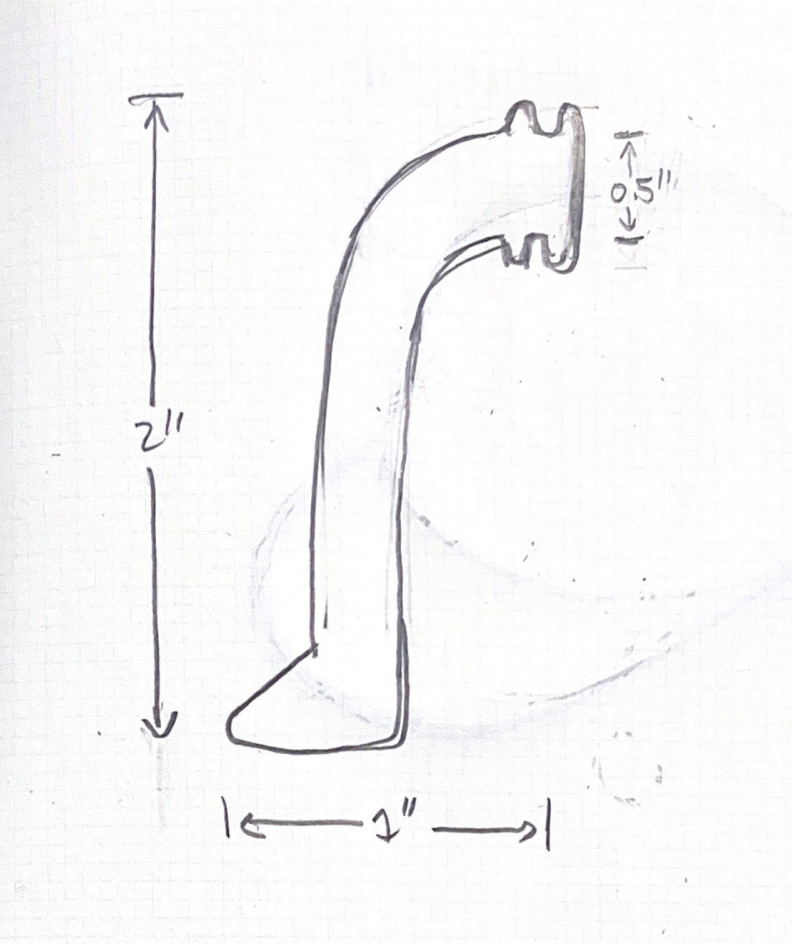

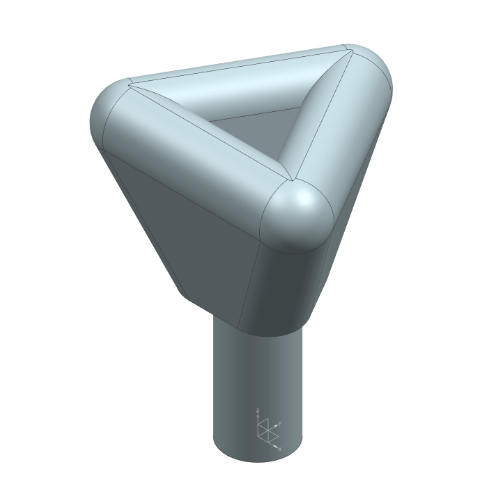

Leg

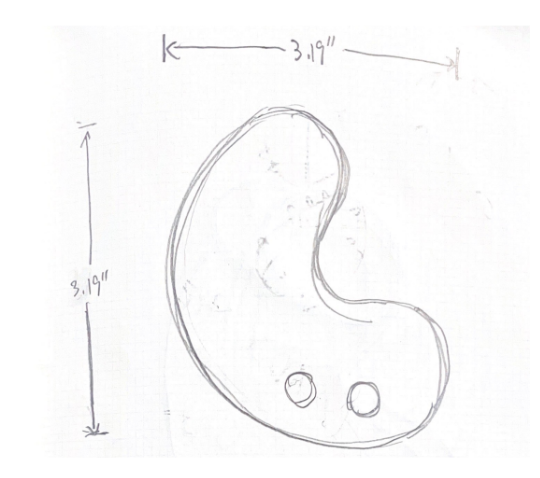

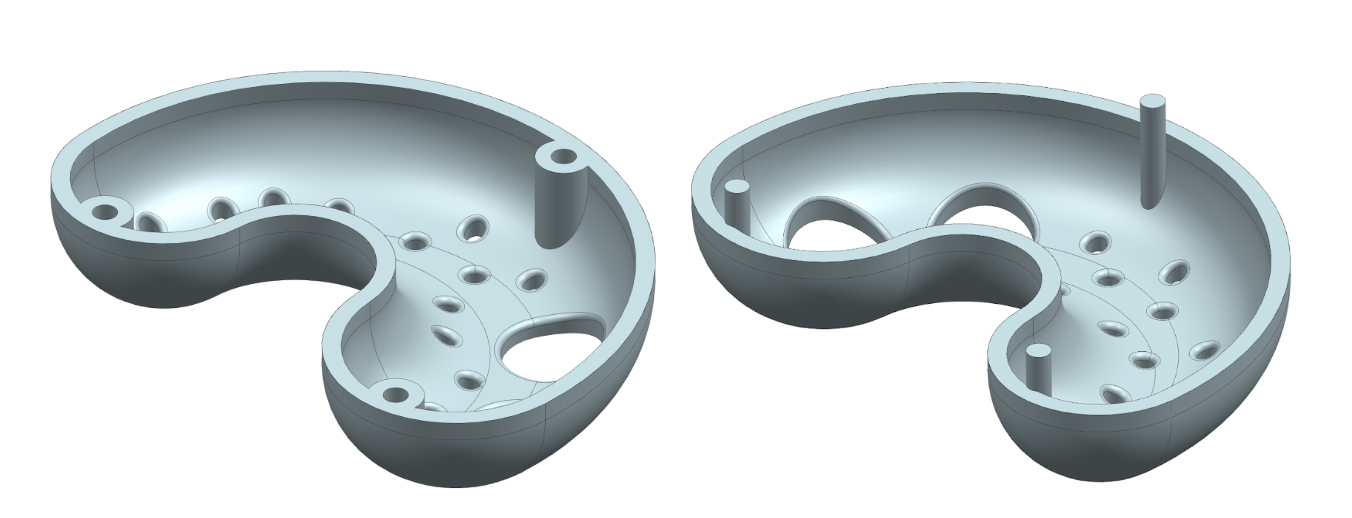

Cashew side

Cashew front

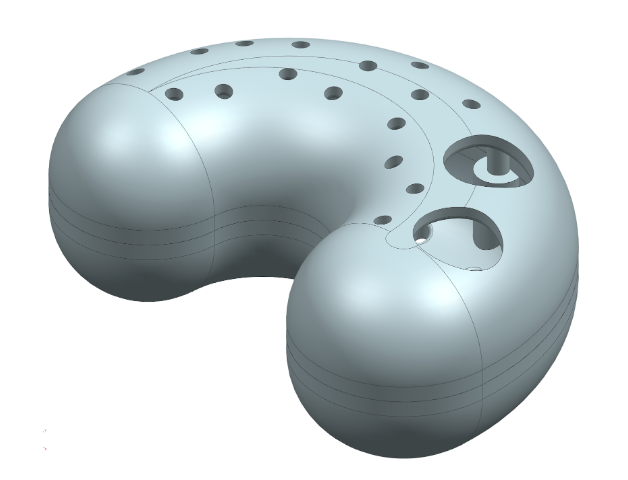

CAD

Next, we modeled each unique component in Siemens NX. Our TA and professor gave us feedback on our geometries which we iterated to optimize for injection molding with regard to component assembly, ease of demolding, shrinkage reduction, and stress concentration elimination.

Mold Design Process

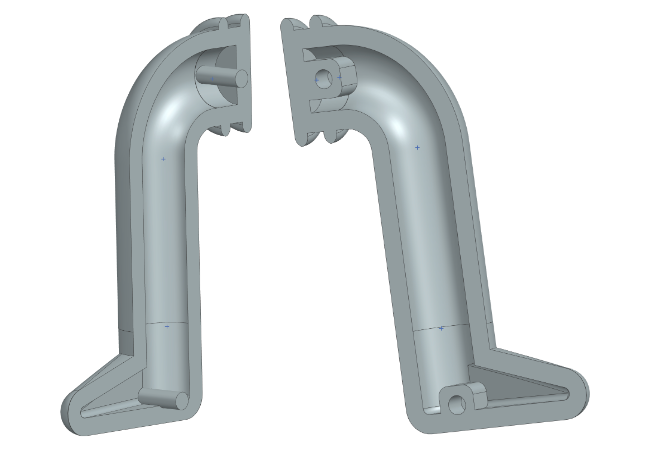

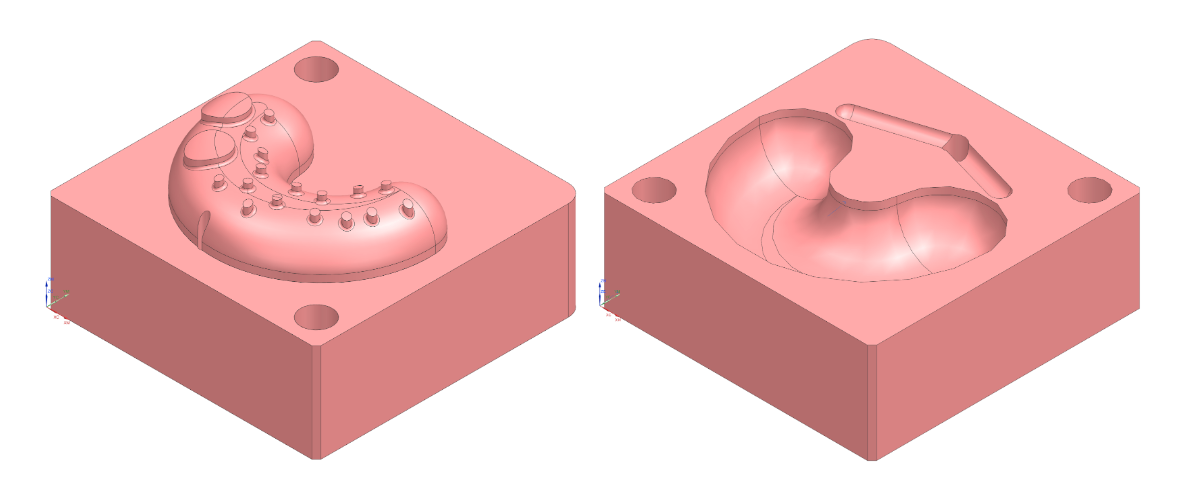

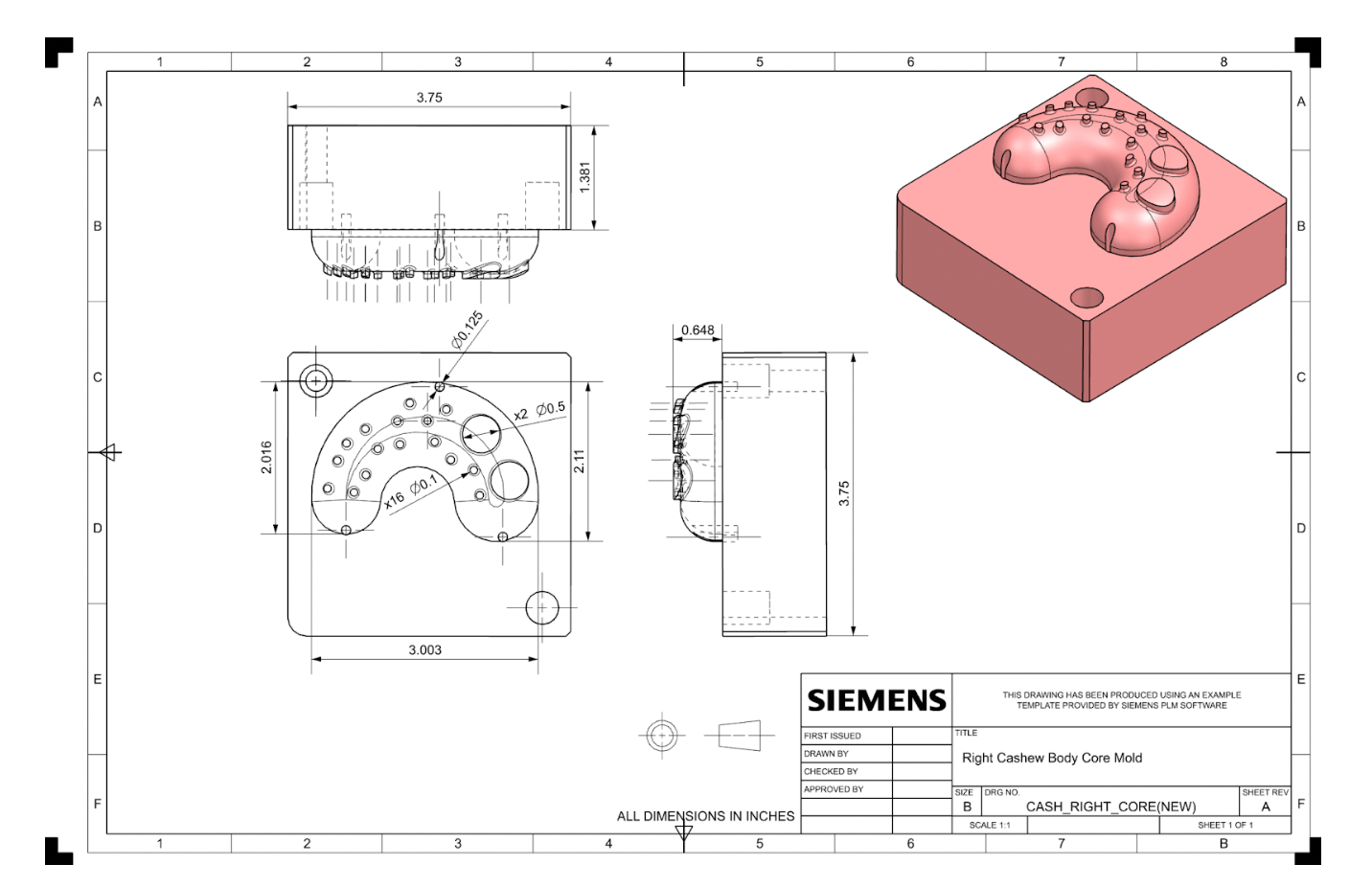

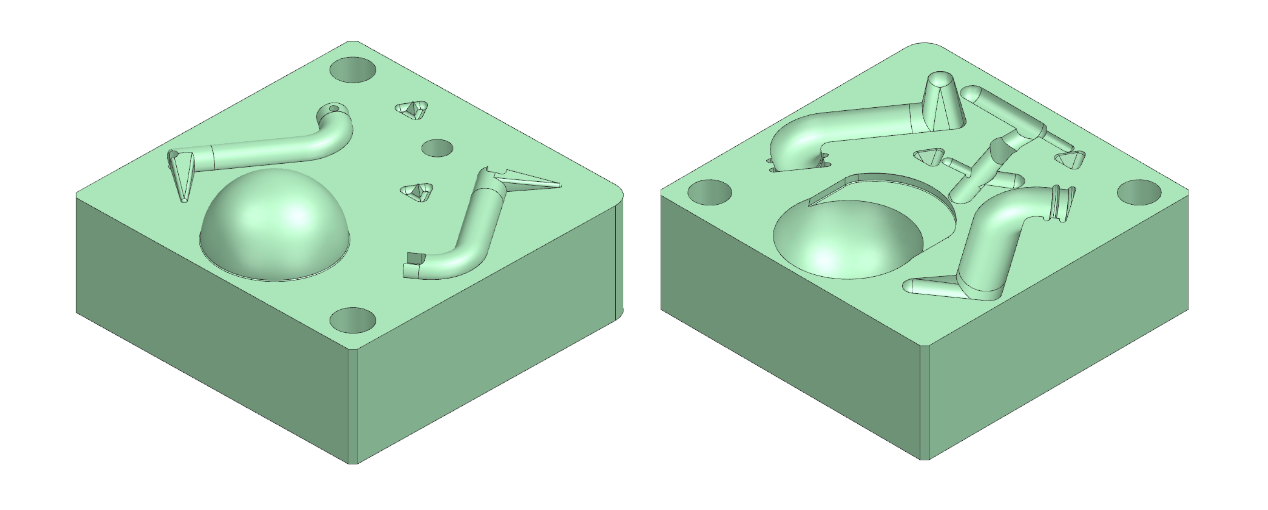

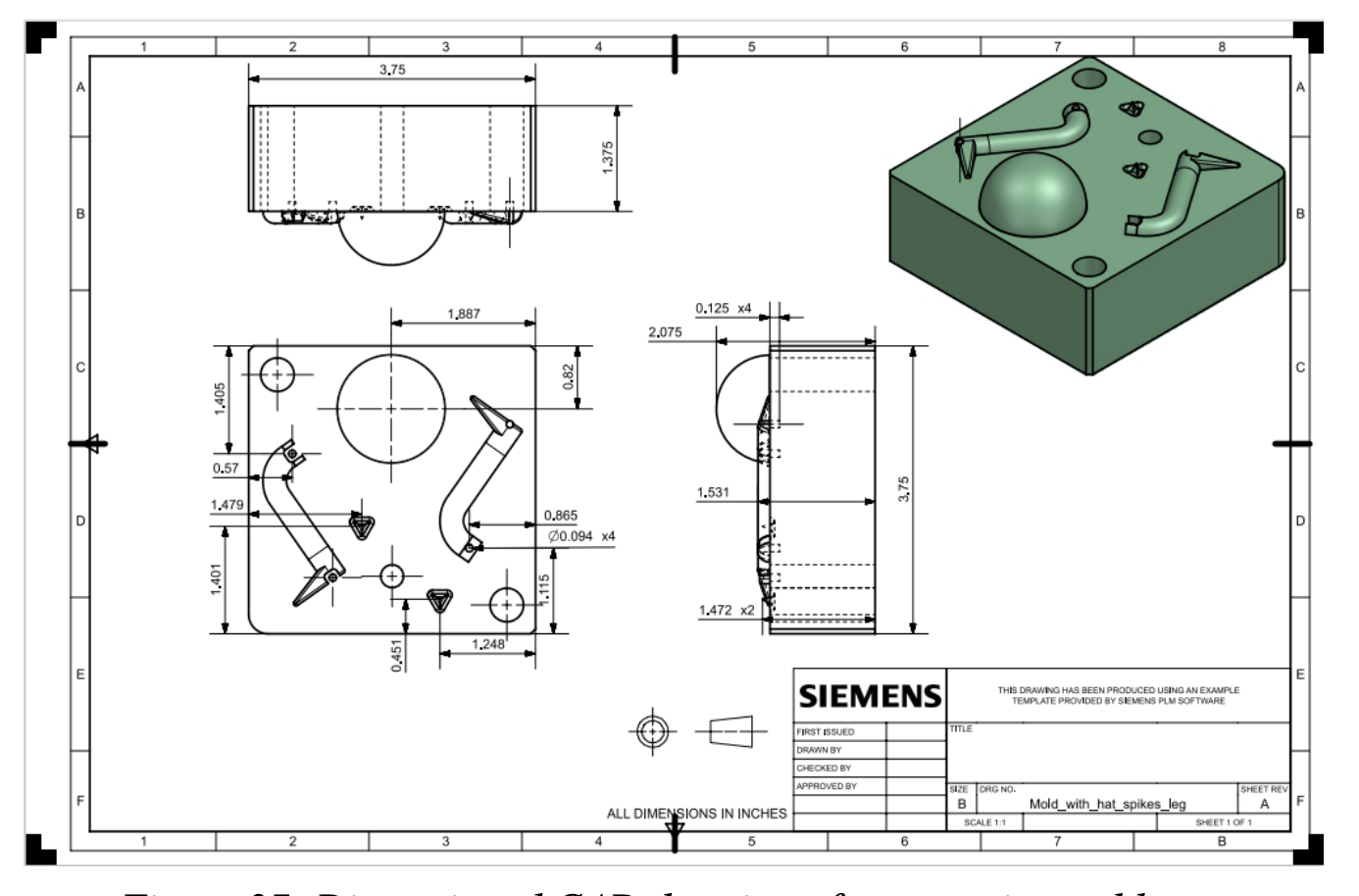

In order to create the plastic parts for the final toy, we first needed to design the negative molds in which the plastic would be injected into. Molding all 6 parts required the creation of 3 sets of molds (cavity and core). We split up the molds by assigning one set to create the left cashew body, one set to create the right cashew body, and one set for the accessories, which refers to the legs, spikes, and the hat. At this stage, the original design was tweaked in accordance with the hardware and tooling that was available to us, and runners and vents were incorporated with appropriate flow speeds in mind. Below are examples of mold CADs and their engineering drawings.

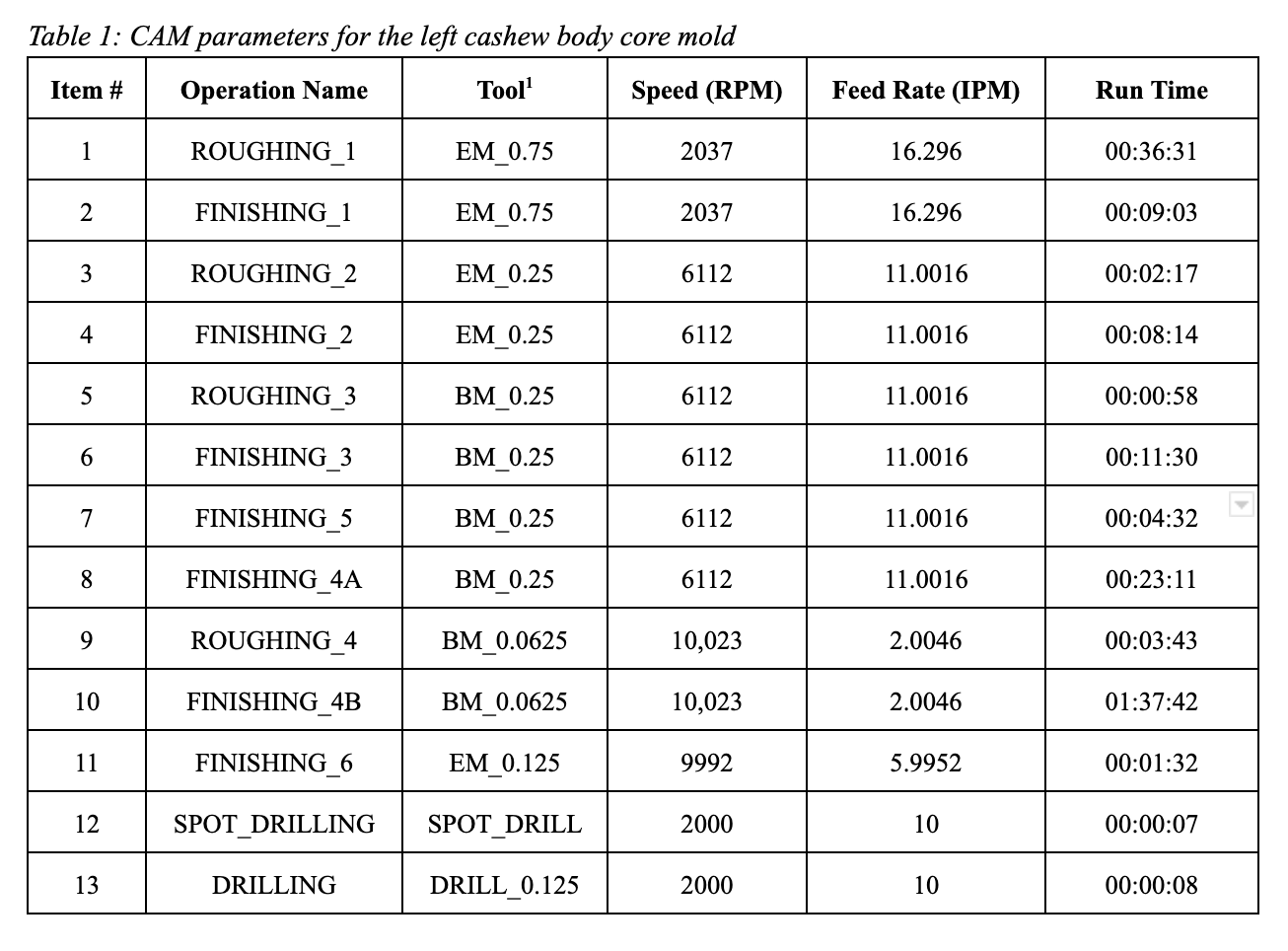

Mold Manufacturing Process - CAM

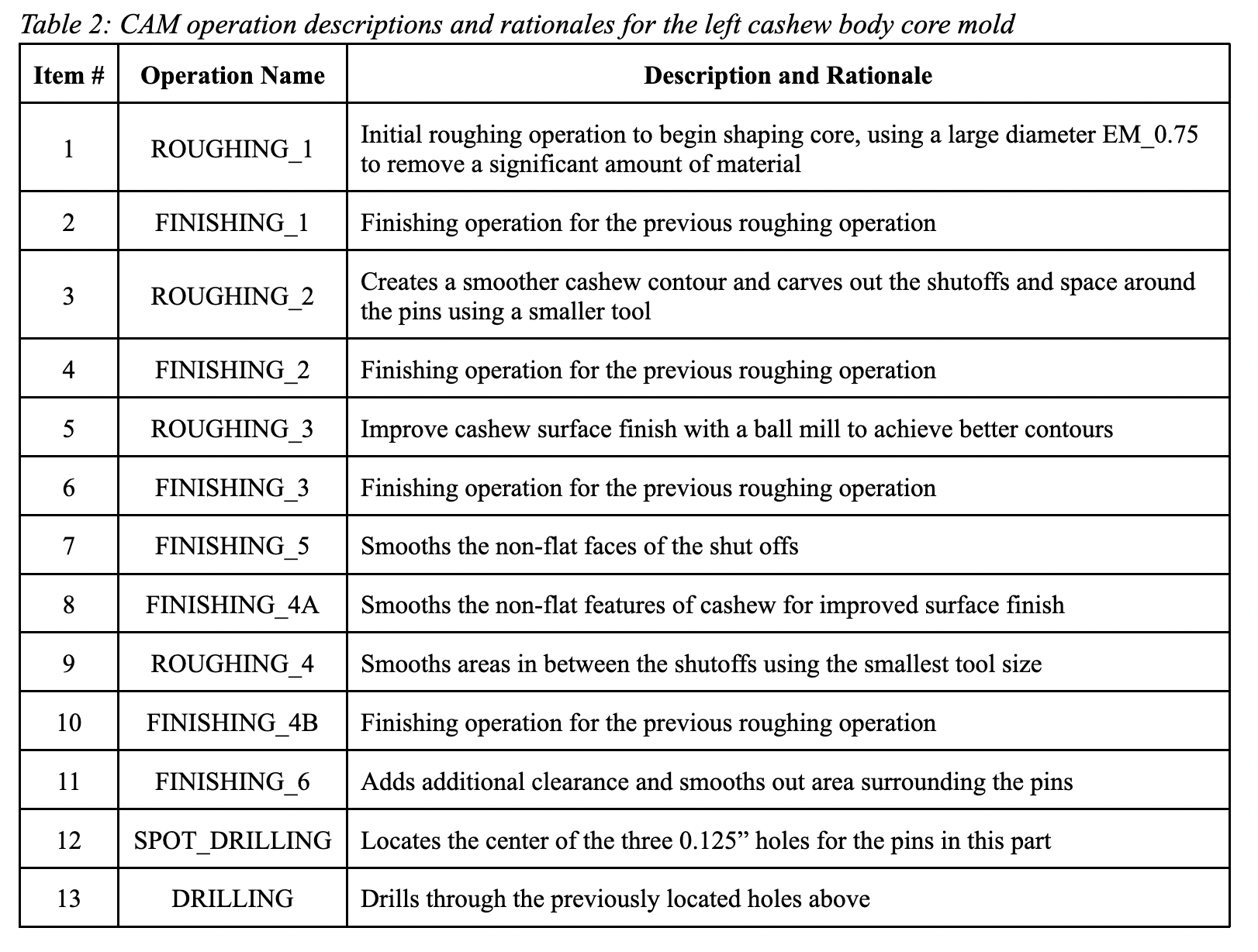

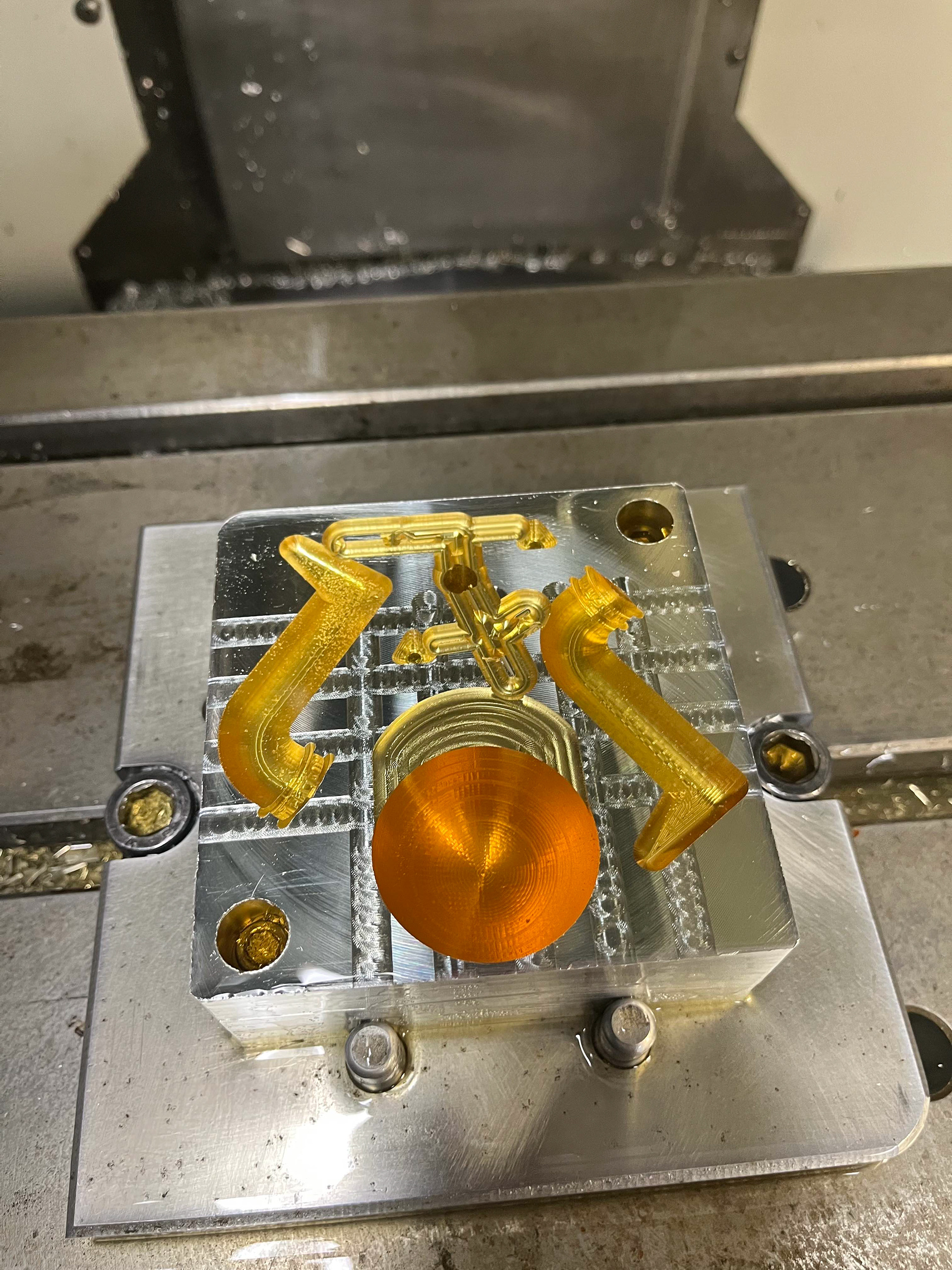

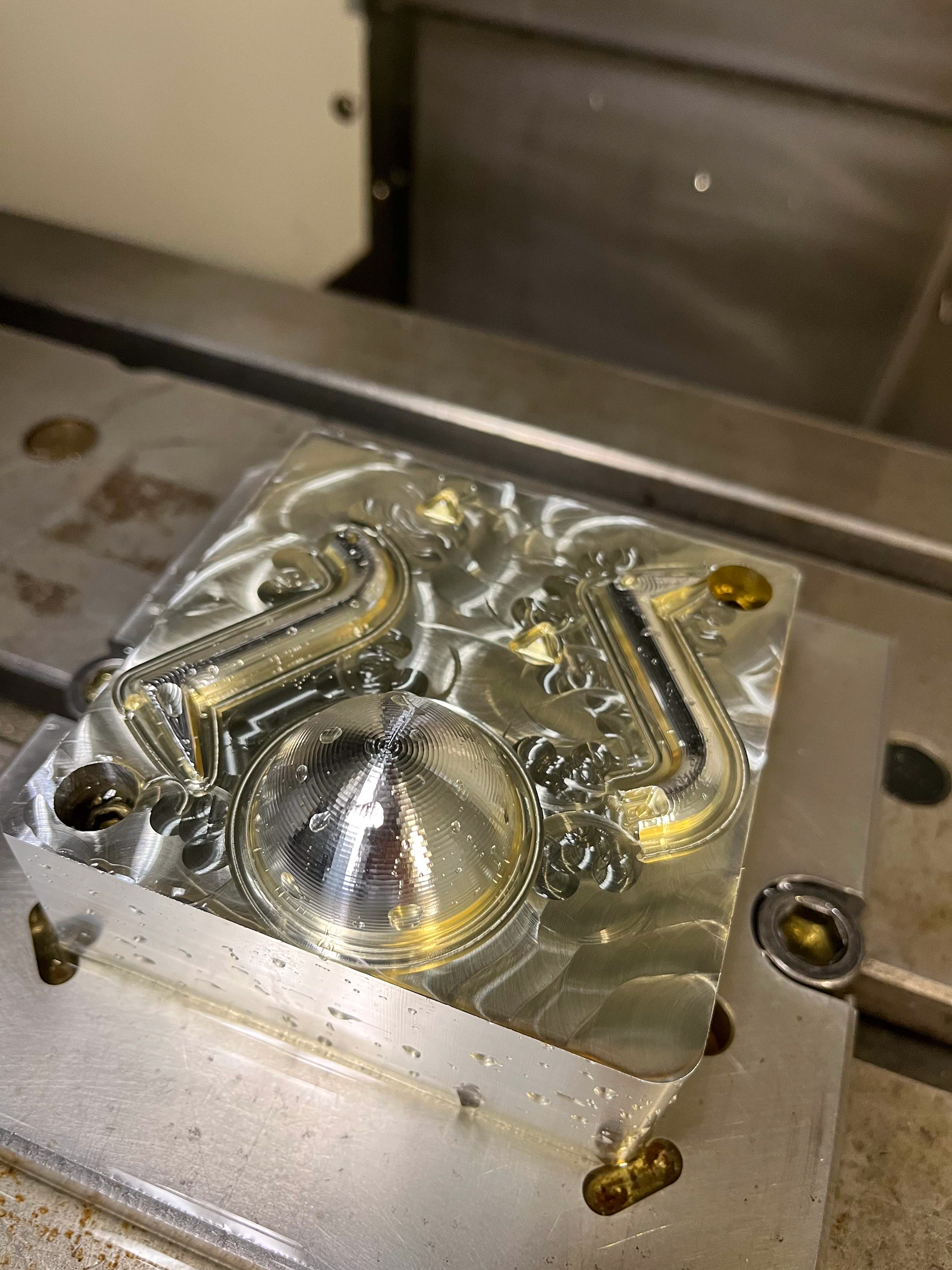

As we required 3 sets of molds, a total of 6 CNC milling mold manufacturing processes were created in NX. The following tables are an example of the CAM parameters and operations defined for the left cashew body core mold:

After all operations were simulated, approved, and exported as G-code, we proceeded to the actual manufacturing of the molds using 6061 aluminum stock and the university shop's Haas CNC mills.

Accessories mold cavity

Accessories mold core

Cashew body right mold core and cavity

The operations were generally successful, with a few machining errors that we fixed in post-processing.

Injection Molding

With our aluminum molds ready to rumble, we proceeded to the most anticipated step—injection molding. We conducted several trials to find the optimal parameters (i.e. temperature, pressure, injection time, color) to conceive the best COVID Cashew components.

The inaugural plastic injection

Freshly roasted cashew halves

Final Assembly and Metrology

Our final production run was 10 complete COVID Cashews, and I think it's safe to say, we delivered. The leg attachments were unfortunately too snug to fully assemble into the body, but we were able to still assemble half the legs for a similar effect.

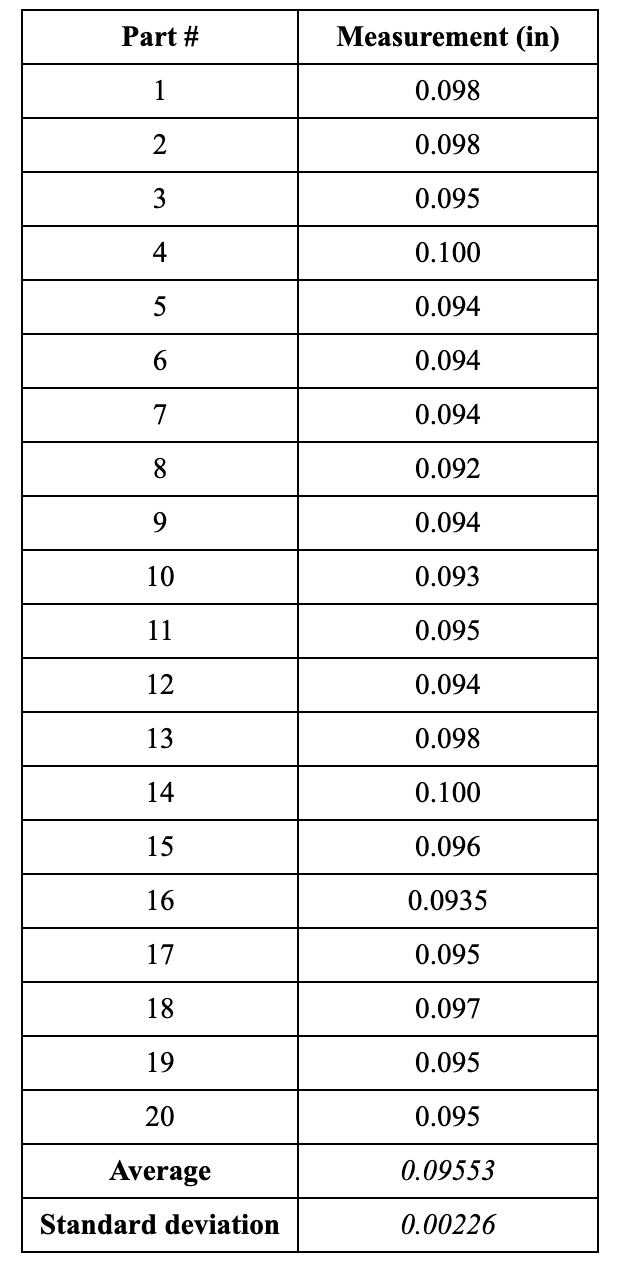

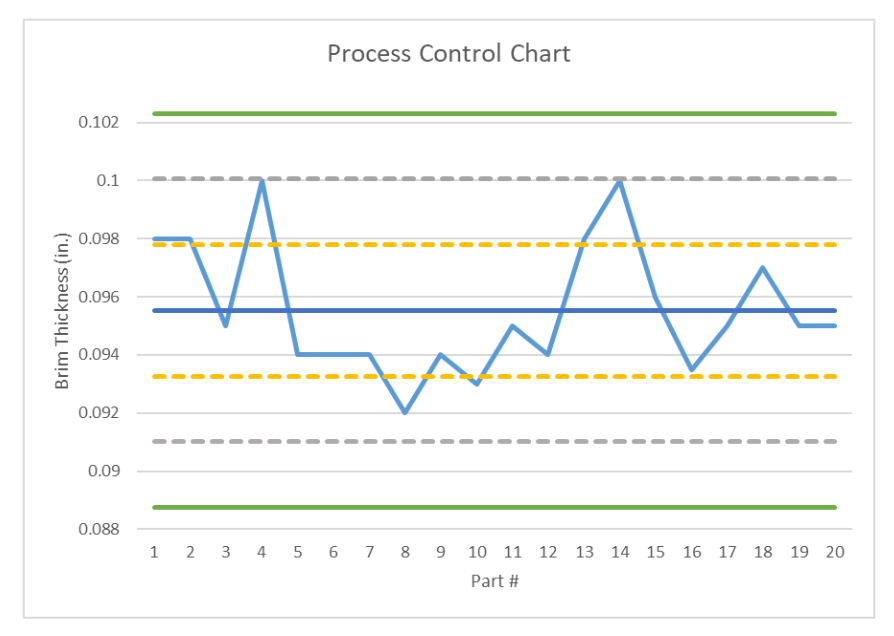

In order to ensure that the resulting parts were manufactured to our initial specifications, we ran a metrology test on one of our components. From the table below, we can see that our produced hats turned out relatively close in dimension to our nominal. We observed a pattern of mostly undersized parts and did not see any oversized parts. Over 20 runs, the average thickness of the flat brim was 0.09553” with a standard deviation of 0.0026”, but 8 of 20 parts were outside of the specified tolerance range. Successfully, this average value we obtained is within the given tolerance of the flat brim dimension (0.1").

Using this data we can also determine how in control the process was. Under the assumption that we have knowledge of our full process, with our standard deviation and average, we find that our UCL is 0.10229” and our LCL is 0.08876”. No points measured during our metrology study exceed any of those figures, but based on points 5-12, however, there are 8 consecutive values below the mean, indicating the process is out of control. These points can be visualized in the process control chart above. This could have been due to the nature of the injection mold process where millisecond variations in time injected and how long we waited before removing the completed mold could have affected the resulting parts.

Our COVID Cashew army <3